Project Overview

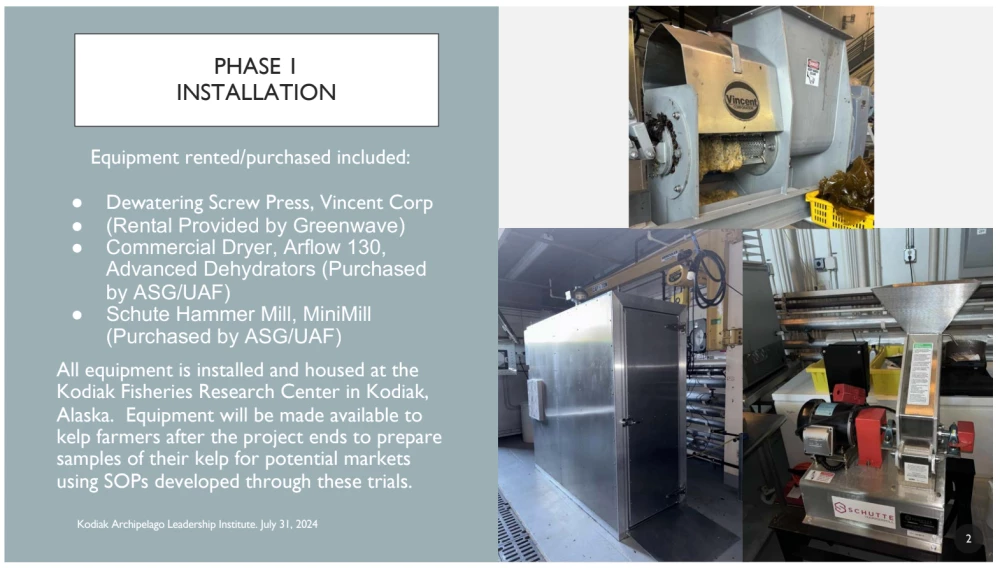

This 12-month project proposes to utilize existing technology for forced air drying and milling to run trials to assess the feasibility of utilizing these technologies on a larger scale for the primary stabilization of farmed kelp. The data collected in the trials, held at the Kodiak Seafood and Marine Science Center (KSMSC), will be used to assess the economic feasibility of drying kelp in rural coastal communities based on power costs and labor, the qualitative traits of dried kelp products (nutrient profiles, salt content, heavy metals, water activity, microbial levels), and create nutrient labels and product specifications for dried kelp products. The proposed drying system will be located at the KSMSC pilot plant and will be available during and after the project for kelp farmers to utilize for preserving dried and milled samples of their farmed kelp. This equipment will be used during ASG hosted seaweed handling and processing workshops.

Interim Report

Forced air drying for the primary stabilization of kelp and milling of dried kelp products has been identified as a research priority yet few studies on the technology required or resultant qualities of the dried kelp have been performed.

This 12-month project proposes to utilize existing technology for forced air drying and milling to run trials to assess the feasibility of utilizing these technologies on a larger scale for the primary stabilization of farmed kelp. The data collected in the trials, held at the Kodiak Seafood and Marine Science Center (KSMSC), will be used to assess the economic feasibility of drying kelp in rural coastal communities based on power costs and labor, the qualitative traits of dried kelp products (nutrient profiles, salt content, heavy metals, water activity, microbial levels), and create nutrient labels and product specifications for dried kelp products.

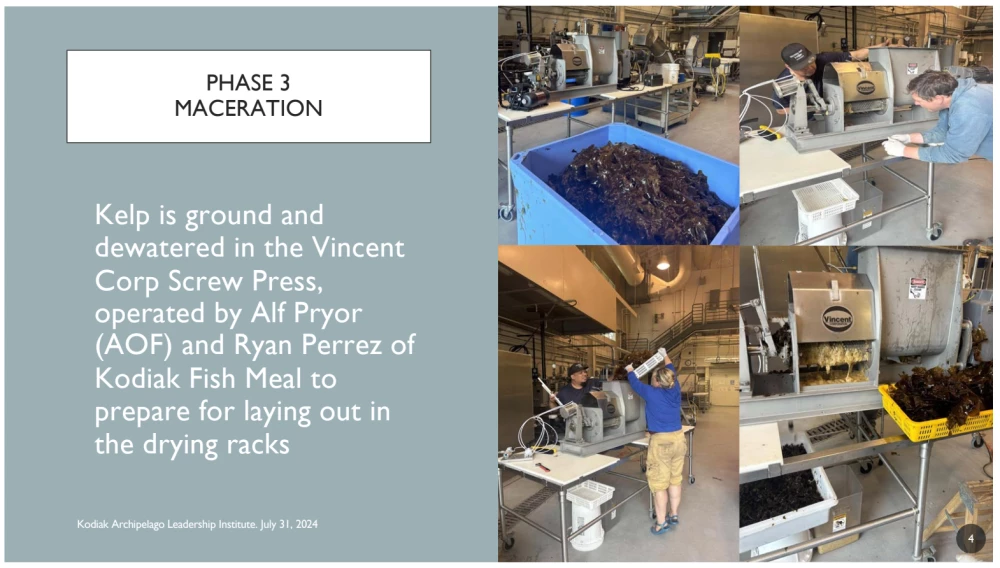

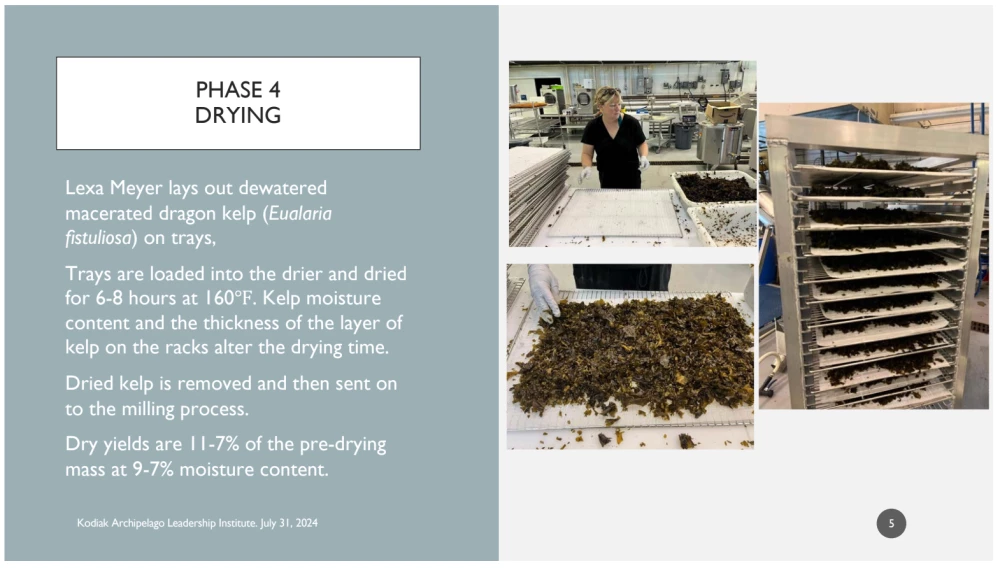

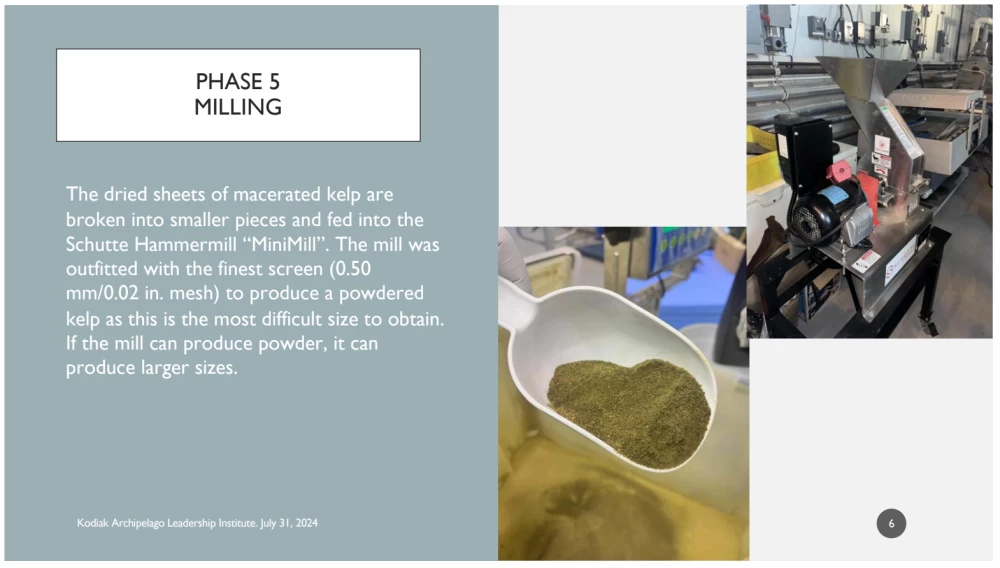

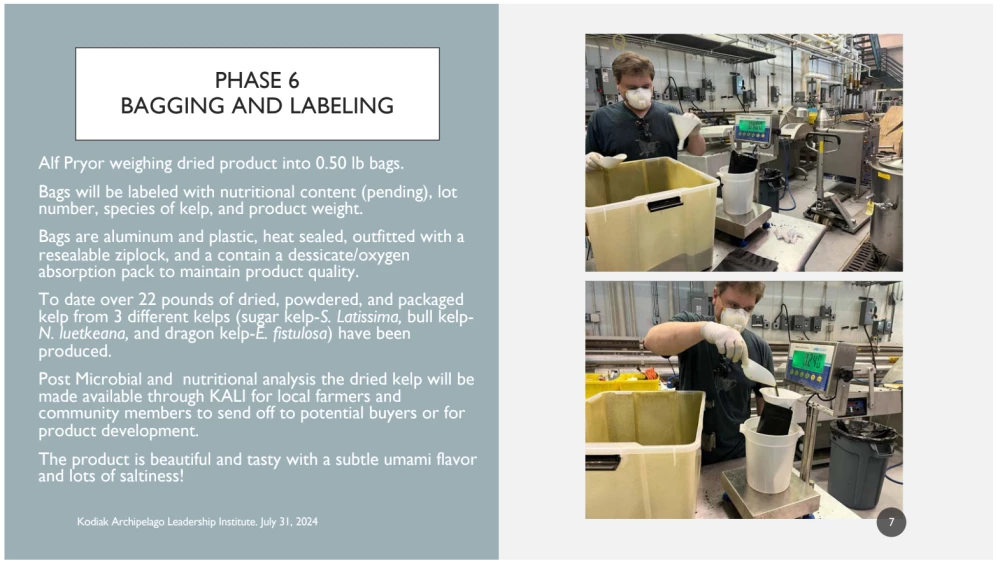

KALI/Alaska Ocean Farms have begun running the drying trials that should end the first part of August. We were delayed starting this project due to the dryer, purchased by UAF/ASG, not being delivered until May 28, 2024. The dryer was installed and became operational on June 18, 2024. The kilowatt per hour gauge has yet to be installed on the dryer but should be installed by the middle of the month. The hammer mill, also purchased by UAF/ASG is onsite and operational. We have identified labs for compositional, microbial, and nutritional testing and will start sending out samples for analysis once kelp is dried and milled. We have dried around 100 lbs of wet bull kelp resulting in just over 11 lbs. of dried kelp. We will begin milling preliminary trials shortly. We are anticipating lower installation and facilities usage costs then in our initial budget and will be requesting a redirection of budgeted funds to additional testing of the dried kelp produced (fertilizer analysis) and expanding drying trials and analysis of dried product to include at least two other species; dragon kelp (Eualaria fistulosa) and split kelp (Hedophyllum nigripes). We will also expand testing to include a water reduction step prior to drying utilizing a pneumatic screw press. We will compare the compositional analysis between kelp that is pressed and not pressed prior to drying. We will shortly submit a revised budget for approval. (see attached picture of dryer with trays loaded with kelp).

Additional Information

The next and final steps are to finalize installation and prepare budget revision for AFDF review when total costs are known, continue drying and milling trials through the summer, send samples for analysis and schedule demonstrations with Alaska Native farmers and leadership.

No challenges anticipated in completing current scope of work by the planned end date. Spending of all awarded funds is anticipated, but after we know the full installation costs we will be submitting a request to modify the budget to include the additional testing as discussed above.

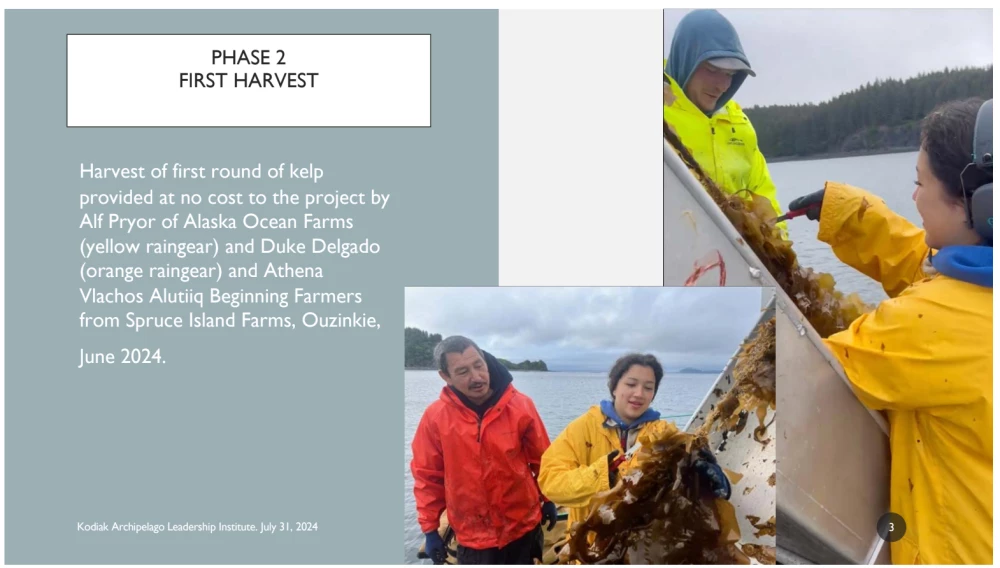

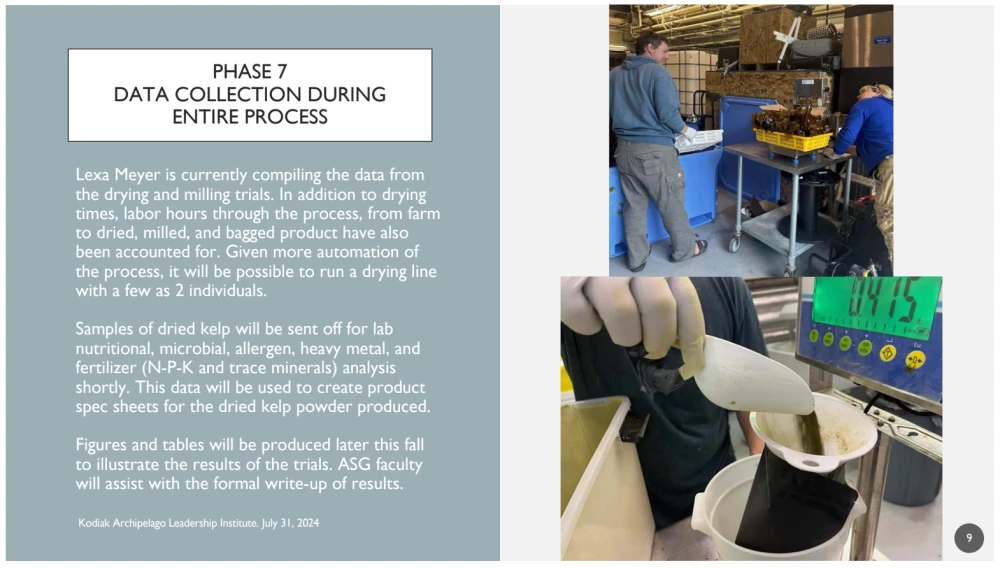

Involvement of Beginning Alaska Native kelp farmers. Two beginning kelp farmers from Spruce Island Farms from the Alaska Native community of Ouzinkie worked with Alaska Ocean Farms in July to harvest kelp for the dryer trials. (see attached pictures)

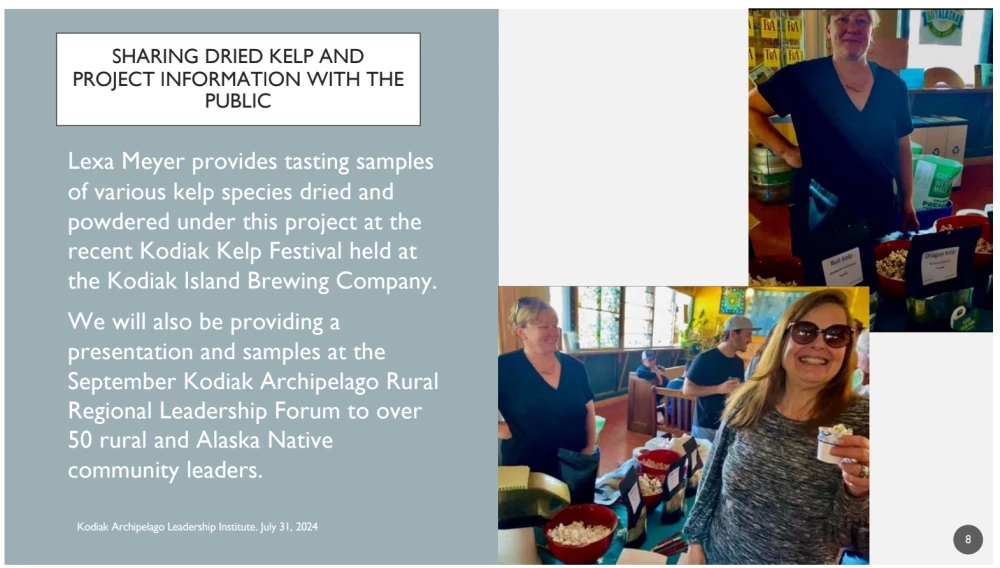

Community and Alaska Native Outreach and Involvement: The Alutiiq Grown Alaska Native farmers are very excited about these trials as we share progress at our Alutiiq Grown team meetings. Through email announcements and direct contacts we will be encouraging beginning farmers to schedule a time to come into Kodiak and view and learn about the drying and milling process. We are also going to have a taste and tell at the September Kodiak Archipelago Rural Regional Leadership Forum that has participation from the leadership of our region’s tribes, Alaska Native Corporations and farmers. This will include bagged samples of dried and milled kelp with their nutritional content along with taste tests of dried kelp on popcorn! Alaska Ocean Farms will be providing a powerpoint that walks through the drying and milling process, and will discuss with the Forum how they see small scale drying and milling working in our region.

Final Report